Wearables/AR

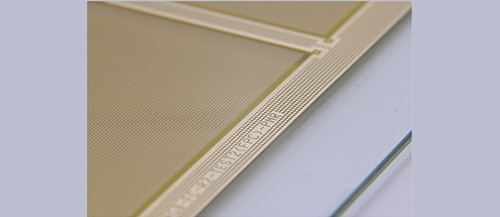

The development of smartphones has gradually reached the limit, while wearable devices and AR glasses are promising with a wide variety of applications, which can change the way we interact with information. PMR provides ultra-thin, transparent and super fine-line PI substrates, combined with pre-drilling and metal line microstructure, which are especially suitable for miniaturized FPC and AR glasses eye tracking applications of wearable devices demanding extreme miniaturization, high-density wiring, transparent and lightweight designs, and effectively improve user comfort and product performance.

Exclusive Patented Technologies

- - -Super-fine/ultra-fine lines

- - Ultra-thin metalization

- - Transparent PI (colorless) metalization

- - Ultra-fine-ine multilayer

- - TDF/CDF de-adhesive material for glass carrier packaging

uLED Substrates

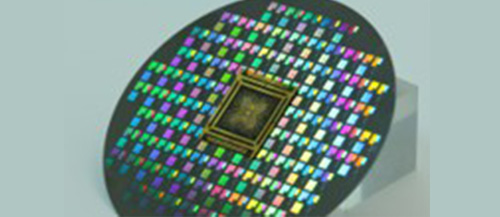

MicroLED displays are assembled by numerous of microLED chips with the advantages of high brightness, high contrast, high color saturation using mass transfer technology, which are suitable for various display applications, including smartphones, TVs, wearable devices, etc.

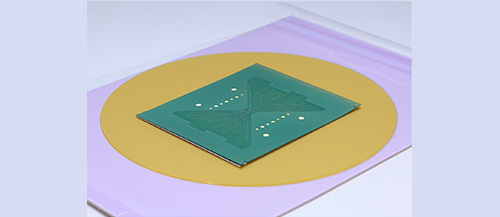

PMR provides high-precision and high-density PI packaging substrate specially designed for microLED MIP (Microchip in Package) massive transfer and packaging. With the characteristics of extreme thin, extremely flat and high reliability, PMR’s microLED substrates are the key foundation materials of next-generation displays.

Exclusive Patented Technologies

- - The PI pre-drilling technology is four times faster than the traditional FCCL drilling, and the processing cost of ultra-high-density microvias is greatly reduced.

- - FOG has higher accuracy and flatness than carrier plate, which is conducive to the production yield of downstream massive transfer packaging, and has a greater cost advantage over glass core.

Camera Modules

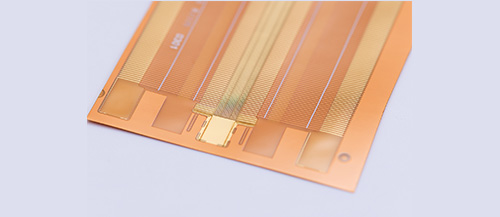

Camera modules have been widely used to capture images and videos in smartphones, cars, smart home appliances and other devices. A camera module is composed of lens, sensor, FPC flexible printed circuit board, image processing chip (DSP) and other core components. The main key factors of camera module design requirement include high-definition, miniaturization, low power consumption and high reliability.

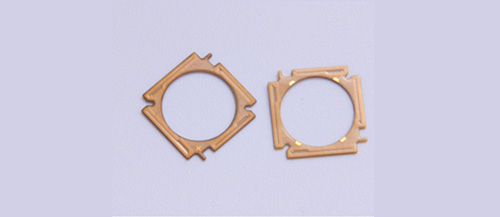

PMR provides specialized high-precision and high-density flexible printed circuits (FPC) used as the fine-pitch coils of camera modules for mobile phones and AR devices, providing stable electronic connection and miniaturization support.

Exclusive patented technologies/cost advantage

- - Ultra-fine-line FPC

- - Super-fine-line multilayer FPC

- - Cost advantage over substrate-like PCB

Interposer/RDL

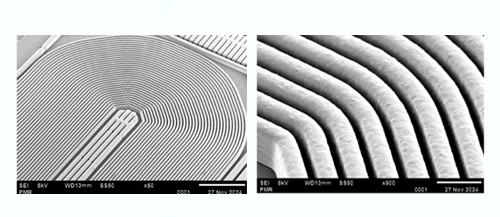

Interposer/RDL (Redistribution Layer) is an important technology for advanced packaging processes in the semiconductor field. The input and output (I/O) welding points on a chip can be redistributed to more convenient positions with a metal wiring layer. PMR's SAP and FOG processes are extremely suitable for high-end sealing plate designs, including chiplet, fan-out, flip-chip and other advanced packaging technologies, which meet the industrial requirements of extremely thin, extremely flat and high reliability. When needed line-widths and line-spaces can reach below 10/10 μm, and the multi-layer structures (3~6 layers) can support high-speed and high-frequency signal transmission to reduce processes and improve yield and cost effectiveness.

Exclusive Patented Technologies

- - Ultra-fine-line SAP

- - Low CTE PI metallization

- - TDF/CDF de-adhesive material for glass carrier packaging

Medical Devices

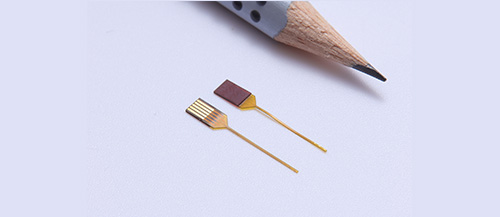

Medical electronic equipment is essential in medical field, which plays an important role in medical diagnosis, treatment and monitoring. PMR's ultra-thin flexible circuit boards can be used in high-precision and high-stability medical equipment, including endoscopes, ultrasonic probes, implantable modules and wearable health monitoring devices, providing good mechanical flexibility and high-reliability electrical performance. PI materials are durable in critical medical environments demanding high temperature resistance and chemical stability, especially suitable for space-limited minimally invasive devices, where need biosensors and micro-probes with flexible packaging.

Exclusive patented technologies/cost advantage

- - Ultra-fine-line FPC

- - Super-fine-line multilayer FPC

- - High aspect ratio (AR > 3) FPC

- - Cost advantage over substrate-like PCB

Implant Bio-Electro Detector

Ultrasound Probe