PI Metalization & Pre-Drilling Technologies

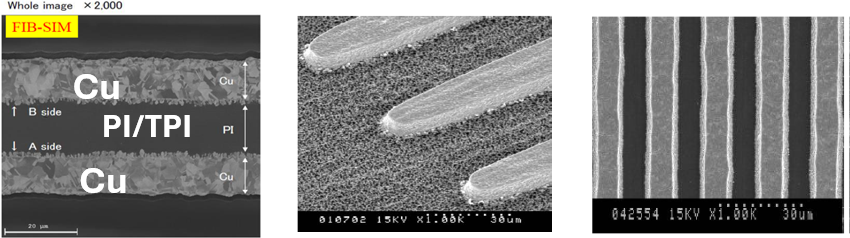

As the core materials of FPC substrates, polyimide (PI) can resist up to more than 400℃ in a short time. With the direct metalization process, PI can avoid the deterioration of traditional adhesion agents at high temperatures and improve the reliability of FPC. PMR uses wet metalization (chemical method) to carry out two steps of chemical nickel plating and electroplating of thin copper on PI films. The advantages of this process are non-adhesive structure, high adhesion, excellent thermal stability, extremely thin metal layer, process flexibility and suitable for large-scale mass production. It is widely used in high-end FPC’s and electronic products.

By adopting the appropriate PI films, different product functions can be realized, such as high transparency, low shrinkage, ultra-thin thickness and other characteristics, which can easily meet the needs of various applications.

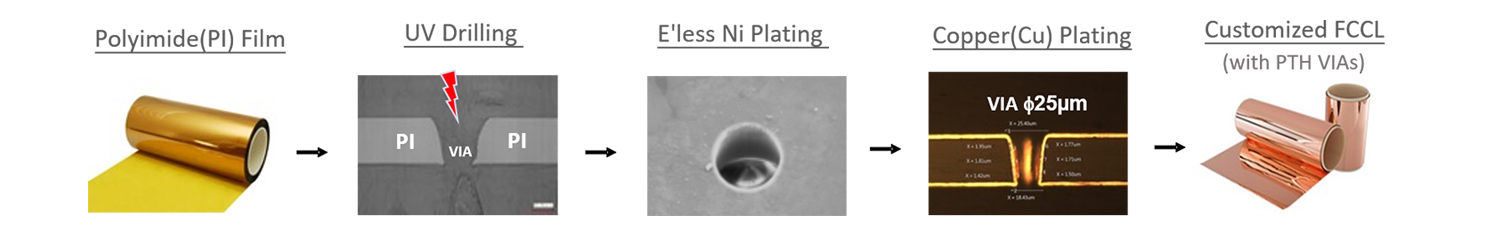

In addition, PMR adopts a new proprietary process to carry out laser drilling and then PI metalization, so called pre-drilling technology, replacing the traditional drilling and metalization of conductive holes on copper foil substrates (FCCL), and greatly simplifying FPC manufacturing. This unique process can significantly improve FPC production efficiencies and reduce production costs.

Pre-laser-drilling can not only be flexibly adjusted to various design needs, but also be integrated with the roll-to-roll process. It can finish the metalization of surface copper and via hole copper at the same time, reduce the risk of metal breakage and thus improve the reliability of conductive via holes, while small via holes will be directly filled which can be an alternative to the complex blind hole process.

| Base film | Features |

|---|---|

| Colorless PI | TT 88~89%, Haze < 0.6% Tg 270 C Thickness 25,50um |

| Low CTE PI | CTE 8 ppm/℃, Modulus 9 GPa Tg 340 C Thickness 12,25,38,50um |

| Ultra-thin PI | CTE 8 ppm/℃, Modulus 9 GPa Tg 340 C Thickness 5~7µm |

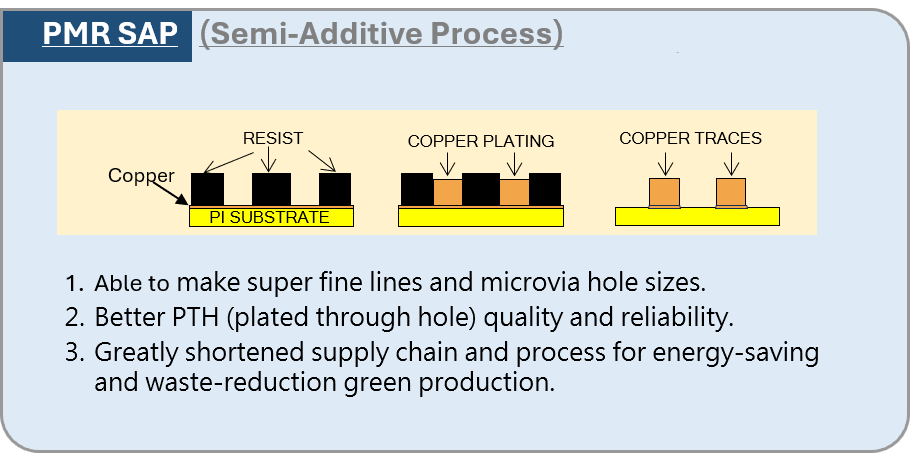

SAP Technologies

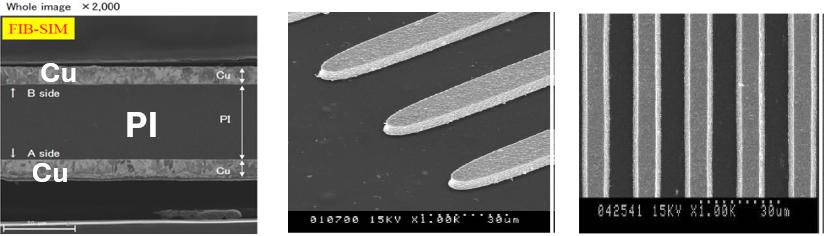

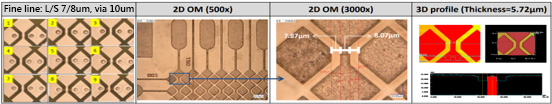

PMR’s semi-addition process (SAP) is a specialized FPC process that combines the advantages of additive process and subtractive process such as high resolution, small lateral etching, and stable line quality. Compared with the modified semi-additive process (mSAP) which takes the ultra-thin copper foil substrate (copper thickness usually 1~3μm) as the initial material, SAP starts with through-hole drilling and then direct metalization, forming an extremely thin conductive layer on PI films. Both mSAP and SAP can achieve much better line resolution than the traditional subtractive process. mSAP can easily meet 20/20μm line width/space, while SAP can even reach ultra fine-line below 10/10 μm.

PI direct metalization + SAP circuit manufacturing

High surface smoothness & high yield of ultra-fine-lines guaranteed

Traditional laminated FCCL + subtractive circuit manufacturing

Roll-To-Roll Ultra-Fine-Line FPC Manufacturing

Fine-line flexible printed circuit (FPC) boards usually refer to those with line widths and spaces less than 30μm and characteristics of high layout density, excellent flexibility and superb lightness. These high-end FPC’s are key to the circuit designs of modern electronic devices, where high-density, miniaturization and high reliability are required, such as smartphones, wearable devices, car electronics, medical equipment, aviation and aerospace components.

Benefiting from roll-to-roll (RTR) production, PMR has successfully integrated proprietary PI metalization and SAP (Semi-Additive Process) technologies, which are essential to fine-line FPC manufacturing with ultra-thin polyimide substrates, to avoid substrate wrinkledness and contamination caused by frequent handling in the traditional FPC production. This kind of automated continuous roll-to-roll process can reduce labor contacts and also ensure high output yields. The unit cost of large-scale RTR production is significantly lower than that of the traditional process.