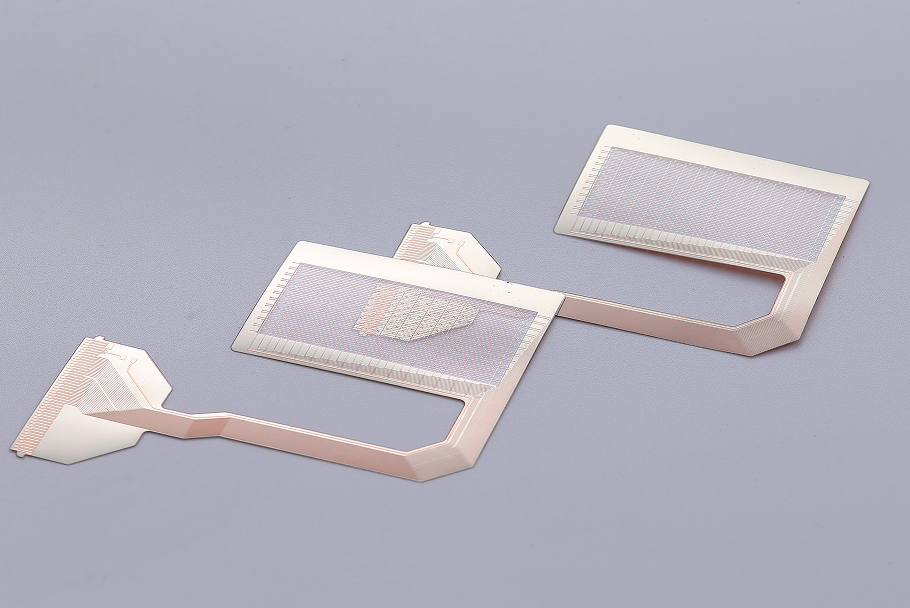

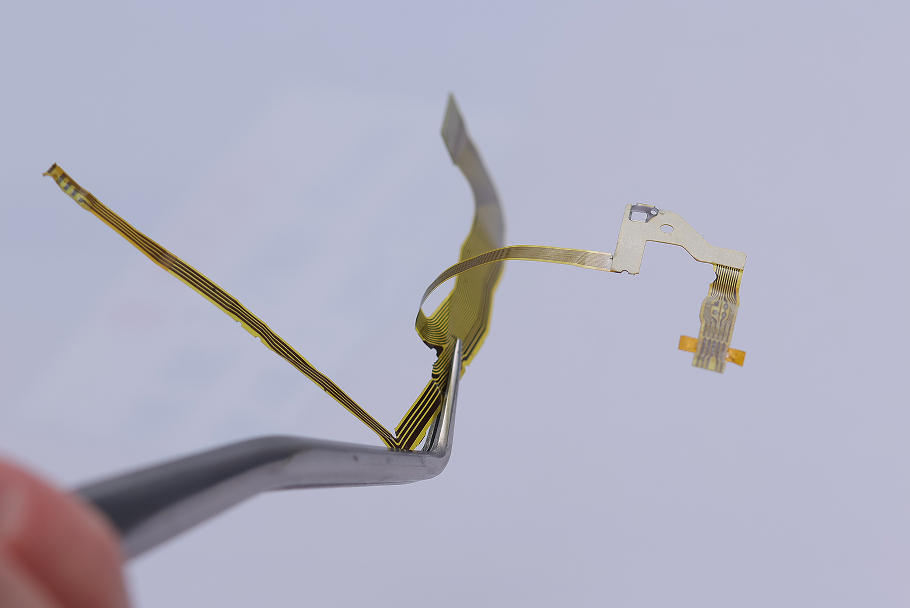

Ultra-Fine-Line Flexes

PMR’s pre-drilling technology can reach via < 25μm, line width/space can reach 10/10μm, which can be used for high-density circuit designs.

● Capabilities

| Min Line / Space (um) |

25/25 | 15/15 | 10/10 |

|---|---|---|---|

| Trace Height (um) |

4~50 | 2~20 | 1~20 |

| Total pitch variation in 50mm.(%) | < 3% | < 3% | < 3% |

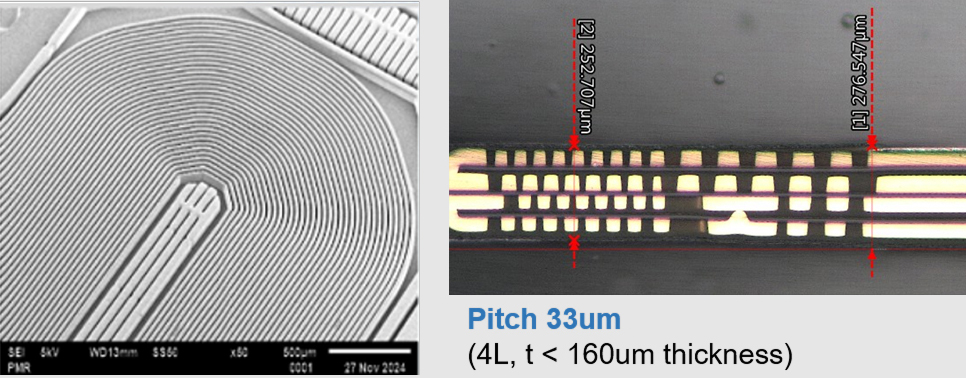

➤ Multi-Layer Flexes

When it comes for multi-layer flex designs, PMR’s semi-additive process (SAP) has more advantages than the traditional subtractive process.

● Characteristics of multi-layer flex technology

- (1) Excellent electrical properties, better heat conductivity and more convenient assembly performance with lightweight substrate film.

- (2) Able to improve the integrity of circuit design.

- (3) Minimizing circuit area and improving the integration of electronic devices.

● Capability : Layer : 3~6 Layers

➤ Ultra-Thin Flexes

Ultra-thin flexes are extremely thin and highly flexible printed circuit films, suitable for small space designs and conducive to effectively increasing the utilization rate.

● Features of ultra-fine-line flex technology

- (1) Extremely thin design: Low thickness, suitable for ultra-thin electronic products

- (2) High flexibility: Bendable, foldable, low R angle, suitable for wearable applications with multiple dynamic folds

- (3) Lightweight: Reducing the weight of equipment and improving portability

- (4) High conductivity: Polyimide (PI) and other materials are used to ensure stable current transmission

- (5) High temperature resistance: Suitable for high-temperature environments to improve the reliability of electronic components

●Capabilities

- PI thickness: min. 4μm

- Line thickness: min. 5μm

- Overall thickness: 4-layer total thickness < 50μm

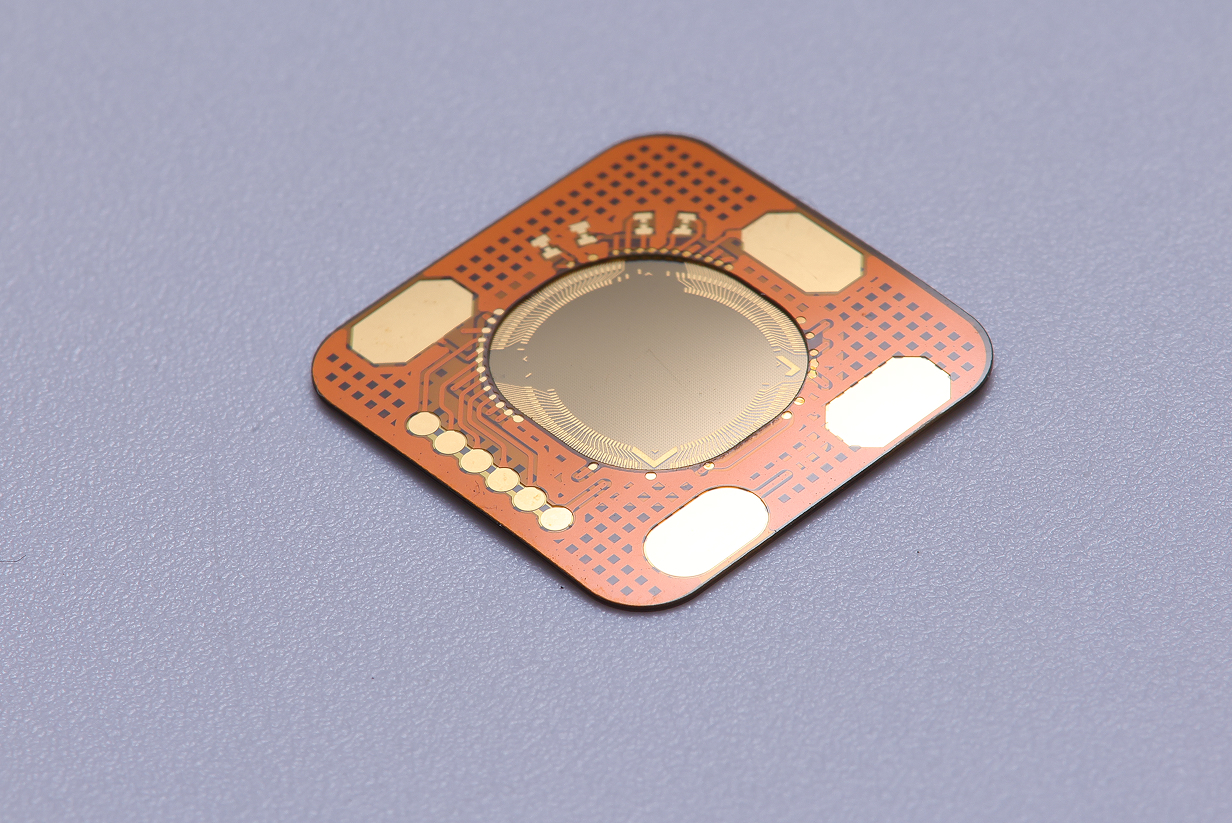

High-Density Microvia Flexes

Fine-line circuit designs are inseparable from the demand for high-density microvias. The pre-drilling technology applied on polyimide (PI) can provide a fast and low-cost process to make microvias (via holes diameter less than 25μm) which can meet the demand of ultra-high-density (20M/m2) microvia products, and is far superior to the drilling process for traditional copper foil substrates (FCCL) in terms of via-hole density and yield.

● Capability

| Through-hole density | VIA Density(VIA/m²) Definition | |

|---|---|---|

| High Density | 500 K/m2 | |

| Super High Density | 5,000 K/m2 | |

| Ultra High Density | 10,000 K/m2 | |

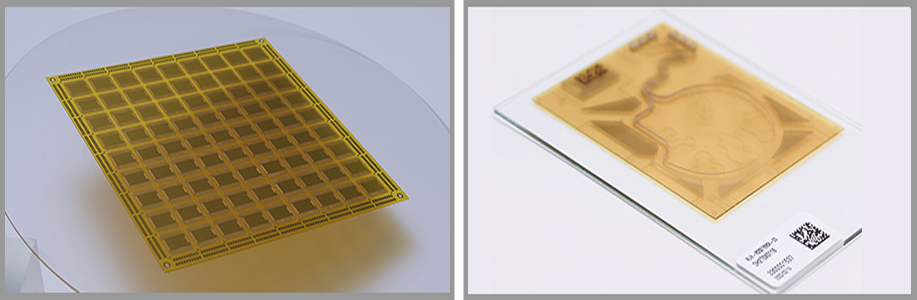

Flex-On-Glass Substrates

Easy-to-bend but thin flexible printed circuit (FPC) is difficult to use in high-precision die packaging (ex. flip chip). Attaching FPC to the glass carrier can solve the control problem of high-precision FPC assembly. After the back-end process is completed, FOG can be easily detached from the glass carrier. FOG (flex-on-glass flexes) can meet the industrial requirements of extreme fineness, thinness, flatness and accuracy, providing the highest precision and high-yield performance for FPC applications.

● Product applicable specifications

- Panel size: 110*75mm ~ 510*515mm

- Lamination accuracy : < 50μm

- Flatness: < 2μm

- Selection of adhesive materials: CDF (cold-debond film)/TDF (thermal-debond film, pyrolytic glue)